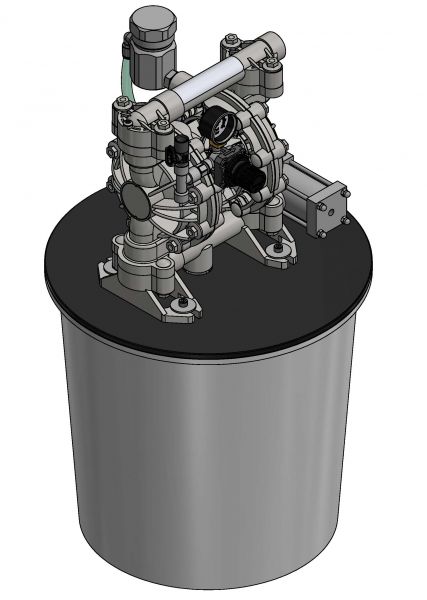

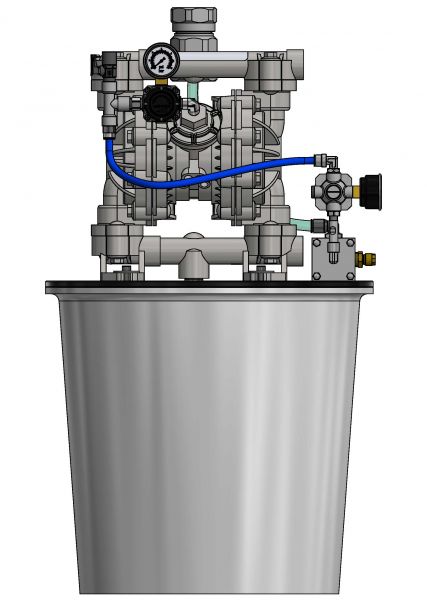

Glue Systems With Diaphragm Pump Series CLD

The glue application system with CLD Series diaphragm pump are indicated for distributing cold low viscosity water-based adhesives (up to 1,500 mPas). All parts that come in contact with the adhesive are in stainless steel or are treated to prevent oxidation. These highly reliable guns require minimal maintenance and guarantee an efficient solution for dosing adhesives at low pressures. Available in different configurations, they can be integrated with accessories such as proportional valves, encoders, photocells and glue level control device.

A stainless steel glue filter, included as a standard feature on all models, has the double function of eliminating glue impurities that could block the nozzles and decreasing the pulsations created by the pump with a sphere on the bottom of the filter. An easily extractable cartridge inside the filter facilitates cleaning operations.

A diaphragm pump with a 1:1 compression ratio, pneumatic controls and anti-stall valve is used.

To control the quantity of glue, in relation to machine speed, a stainless steel pressure regulator can be mounted with a 1:1 ratio, controlled by a proportional valve or set manually.

The pump is mounted on a plastic lid which is easily positioned on standard buckets (capacity of 20-30 lt), and can be transferred to a bucket filled water to wash the system.

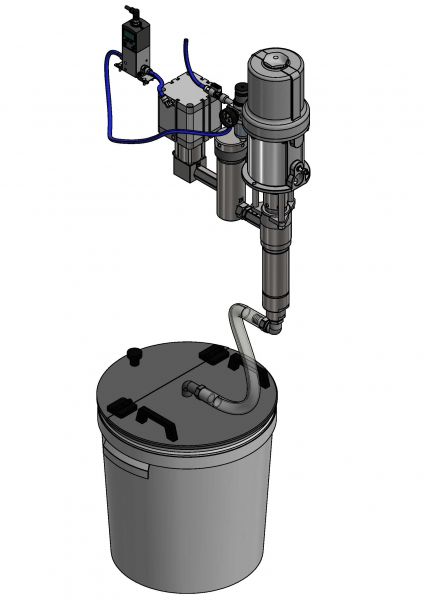

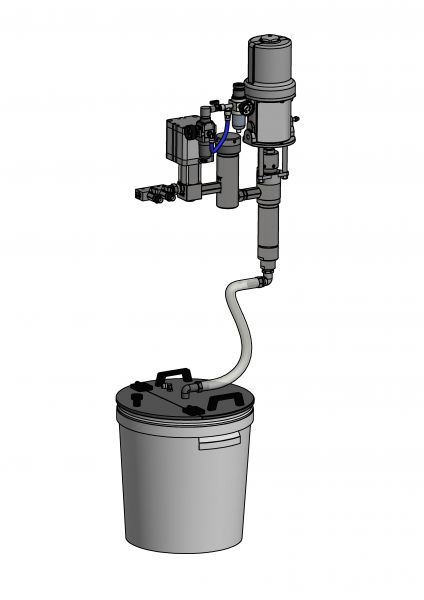

Glue Systems With Piston Pump Series CLP

The glue application system with CLP Series piston pump are indicated for distributing cold medium viscosity water-based adhesives (up to 10,000 mPas). All parts that come in contact with the adhesive are in stainless steel or are treated to prevent oxidation. These highly reliable guns require minimal maintenance and guarantee an efficient solution for dosing adhesives at high pressures. Available in different configurations, they can be integrated with accessories such as proportional valves, encoders, photocells and glue level control device.

A piston pump with a 4:1 compression ratio with pneumatic controls is used.

To control the quantity of glue, in relation to machine speed, a stainless steel pressure regulator can be mounted with a 4:1 ratio, controlled by a proportional valve or set manually.

A stainless steel glue filter, included as a standard feature on all models, has the double function of eliminating glue impurities that could block the nozzles and decreasing the pulsations created by the pump with a sphere on the bottom of the filter. An easily extractable cartridge inside the filter facilitates cleaning operations.

The pump is mounted on a plastic lid which is easily positioned on standard buckets (capacity of 20-30 lt), and can be transferred to a bucket filled water to wash the system.