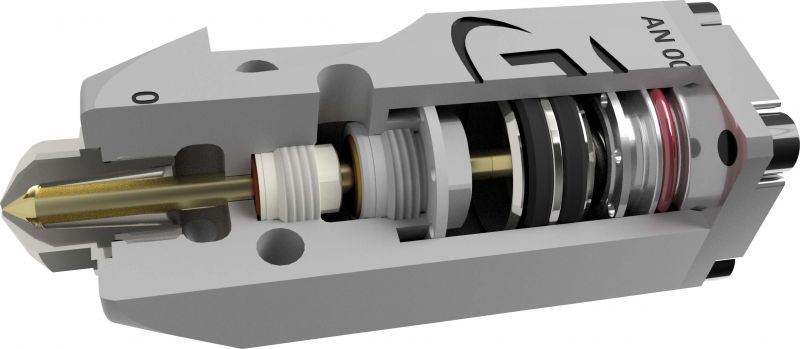

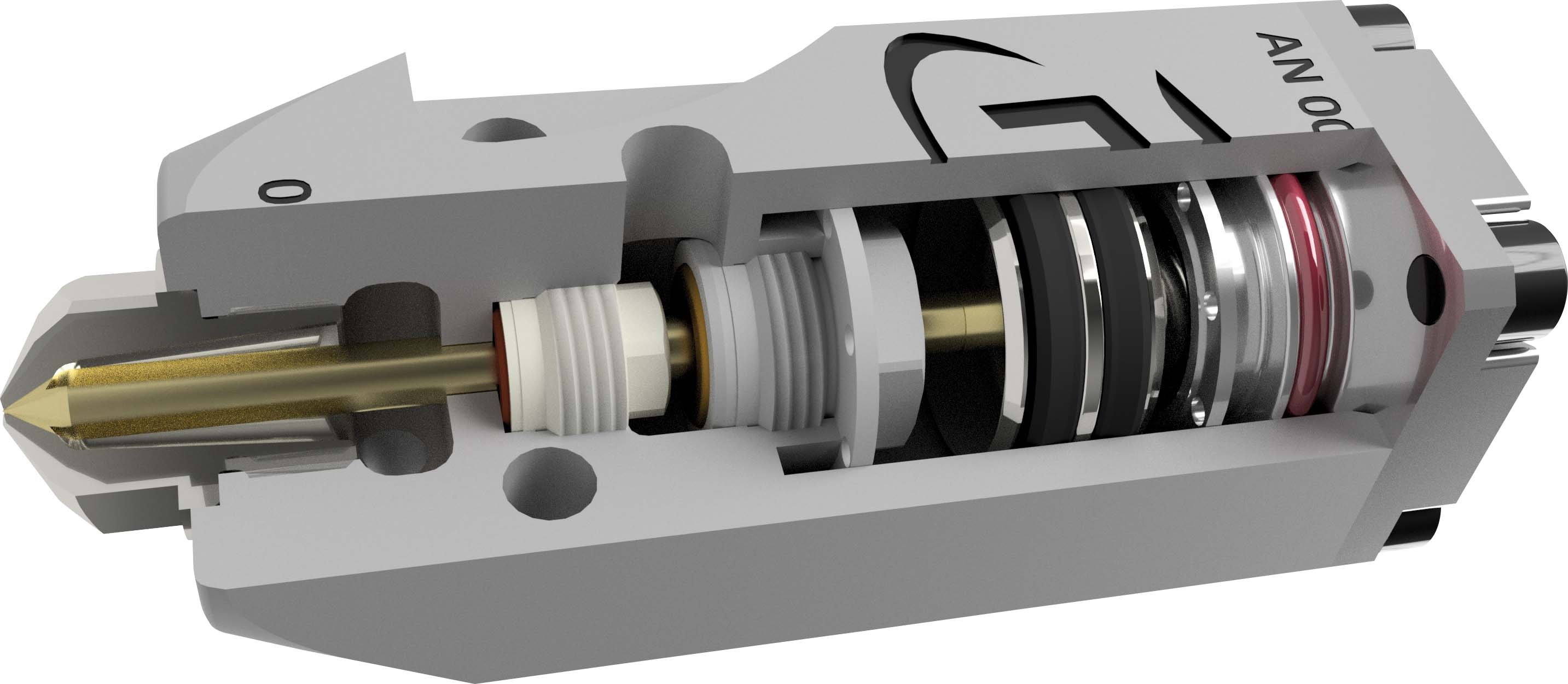

The new double effect modules series AMX-45 E2 AO/AC ensure a precise and regular glue application. This level of performance is possible only because of the special attention dedicated during the design and construction phases. The main characteristic of the AMX-45 E2 module is its innovative gasket system with double interchangeable cartridge, which guarantees a perfect seal at high pressures and temperatures in addition to a simple, inexpensive, and long-lasting maintenance. The module is activated by compressed air both in opening and closing. This functionality, together with the Zero-Cavity nozzle, increases the application's speed and the removal of any tail or "angel hairs" making a clear cut-off (differently from modules with spring closure). A wide range of nozzles (in different special configurations and materials) allow even the most demanding Customer to always find a solution to every gluing problem.

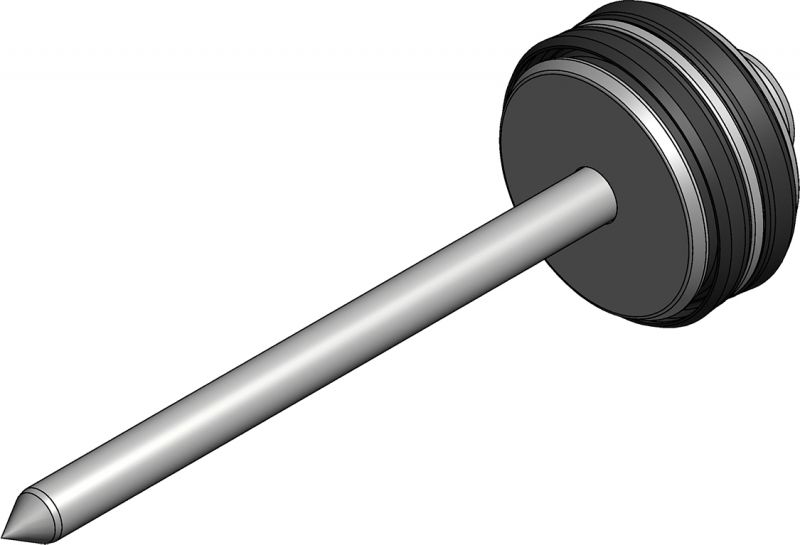

The hard metal needle guarantees reliability, precision, top performance and a practically unlimited lifetime.

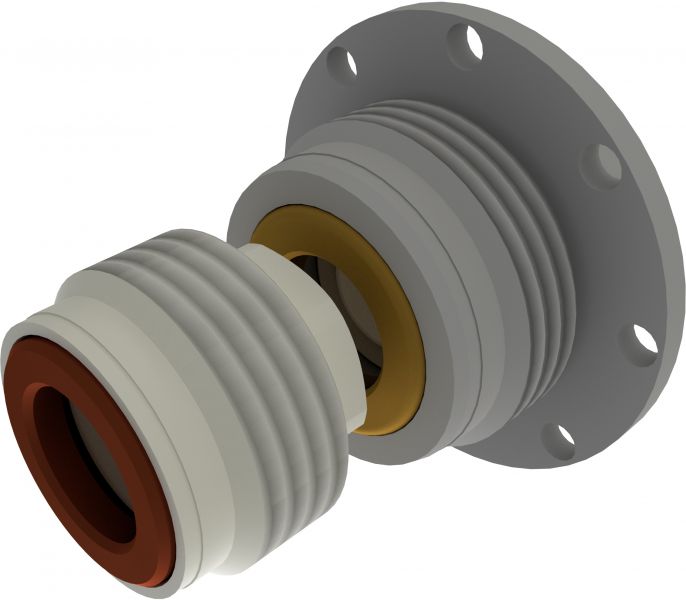

The innovative double interchangeable gasket cartridge system is specifically developed to guarantee a perfect seal at high pressures and temperatures. It also ensures simple, cost-effective maintenance and a long product's lifecycle. Cartridges can be easily unscrewed and replaced with new preassembled cartridges in order to have modules always working properly, without compromising reliability, quality or precision.

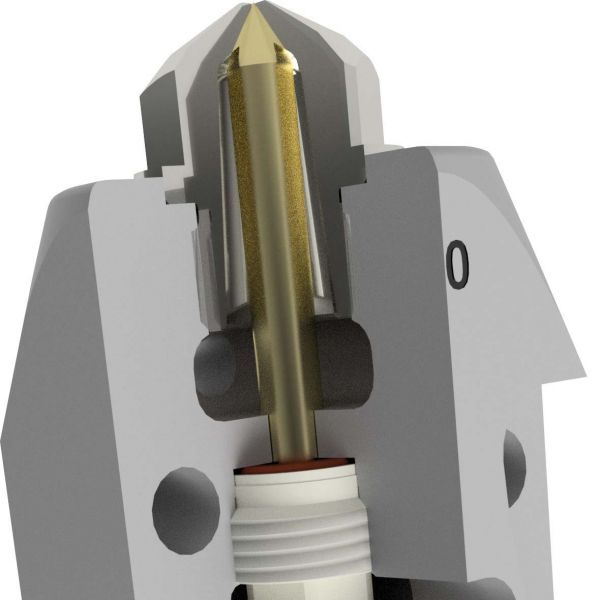

Modules are supplied with Zero-Cavity nozzles. The Zero-Cavity closure system is an innovative self-cleaning system: the needle fits directly into the nozzle hole and breaks up any residues. Therefore, nozzles are always clean, and the whole system always works smoothly.

Brass module casing improves thermal conduction and mechanical stress resistance. The non-stick hard oxidation treatment on the external surface expedites and simplifies maintenance procedures, and reinforces the module. It's used and suggested for applications requiring work speeds of up to 8,000 strokes per minute.

A wide range of nozzles are available in different configurations and special models, depending on the customer's specific needs. Nozzles can be designed in an array of sizes, and manufactured in several different materials.

Stainless steel nozzles mounted as a standard feature on standard modules. Nozzle hole diameters range from a minimum of 0.25 mm to a maximum of 1.2 mm. The Zero-Cavity closure system is an innovative self-cleaning system: the needle fits directly into the nozzle hole and breaks up any residues. Therefore, nozzles are always clean, and the whole system always works smoothly.

Size range up to 65 mm long: specifically designed to distribute glue in hard-to-reach places, or in narrow or deep spaces. Construction material: special aerospace alloy with thermal conduction properties eight times higher than a normal bronze alloy (nozzle maintains constant temperature along its entire length). A Zero-Cavity mini-nozzle, available in different diameters, is screwed to the adapter.

Construction material: aerospace alloy with increased thermal conduction properties and higher tensile strength than steel. No insert ensures a very precise flow of adhesive - even at minimum pressures. As a result, strings and smudging are no longer a problem. Non-stick external coating with the same surface hardness as tempered steel. Available in different sizes: straight or at 90° angles.

These products consist of a threaded stainless steel adapter and 1-2-3-4 way brass nozzles with different angles. Usually, they are used where it is impossible to use guns with several modules, or where several glue lines must be applied in narrow areas.

Special Series nozzles have innovative technical specifications. Construction materials provide very high resistance to wear and breakage, and thermal conductivity level higher than traditional grades of steel. Rapid heat transmission - at least eight times higher than normal - is the advantage to this type of material. Design: enhanced reliability, even for multi-way nozzles. Distribution specs are similar to Zero-Cavity nozzle specs.